Originally Posted by

rs250nut

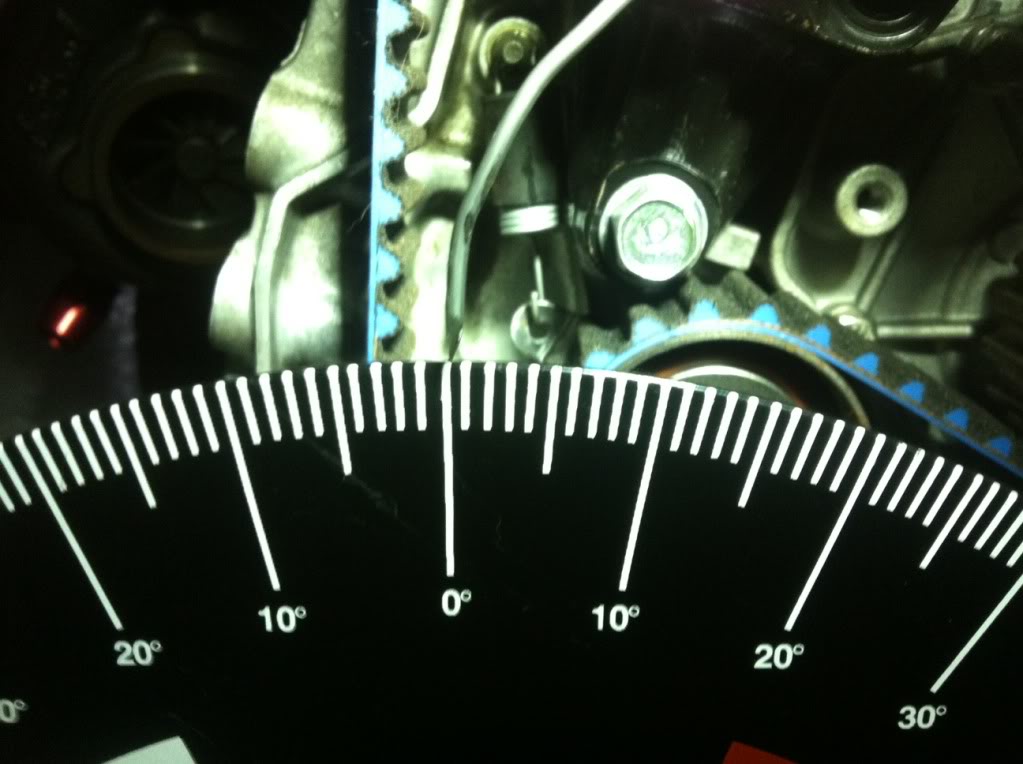

I would never trust some marks on the pulley, do it right with a degree wheel, with the piston stop in the engine it will never reach tdc as you are stoping it just short, and the same happens when you turn it the other way, you end up just shy of tdc. Mid way between these two points is bang on tdc, for example if you turn it clock wise and end up at say 17 degrees btdc record this, next turn the engine until it stops in the other direction say you have 11 degrees atdc, what's the midway point between these two reading on your degree wheel? 28 devided by two is 14 now with the piston stop removed you can reach tdc. The degree wheel will not be reading 0 degrees it will be at 3 degrees now, without moving the crank either move your pointer to 0 or adjust the degree wheel. This is the most important part of degreeing in a cam,if you don't get this right everything will be off.

The next part can be done a number of ways, this is the easiest way, set your dti up on number one bucket, an extension on the dti may be useful here or use a push rod centred in the bucket, find the base circle of the cam shaft, the round bit without the lumpy bit on, next turn your degree wheel to what the cam manufactures says peak lift should be at, as in my link in a previous post this should be 112 degrees atdc, now loosen your cam gear bolts and turn the cam shaft without moving anything else until you see the highest reading on the dti gauge. This is now bang on full lift where it should be. You could go one step further and find the centreline of the inlet profile yourself, but this maybe one step to far at this point.

All this said and done now its best advised to book some dyno time to properly dial in the cam to find out where your engine likes it best, don't go to far without measuring p2v clearances in the case of a c1j or both v2v clearances and p2v clearances on a twin cam engine.

Reply With Quote

Reply With Quote

couple of questions:

couple of questions:

time will tell (once I have it dyno'd) if it has made much difference

time will tell (once I have it dyno'd) if it has made much difference