GT2560 is garrett speak for T28. It doesn't tell us the compressor trim or tubine housing size through.

I still think it's something more fundimental though. Peak power was happening at 6krpm. Even with a carb the piper 285 should make peak power nearer 6700rpm let alone when it's retarded 4 degrees. Bit of a funny one that I don't have an answer for, sorry

I reckon your rollers need looking at

Pulled that turbo off and apart from a cracked wastegate area it all looks ' normal ' T3 60 trim .48 exhaustFeck knows why it does feck-all till 4k

Well not to point fingers or anything but said turbo company have rebuilt a turbo for HAndy that should've been good for 400bhp+ but fitted a turbine wheel and housing that could bearly flow 300bhp.

Get the rear housing off Andy and measure that turbine wheel ASAP. The turbo you've got was The same as mine before they did any work on it and mine made 212bhp at 18-19psi revving to 7k, yours should be able to do it too. Your setup is basically the same as mine was, if mine can do 212bhp with a few issues that i hadn't sorted by the time it was mapped then yours should too.

Have you had any head work done on yours Andy?

Definetly getting full throttle? something silly maybe?

I would be doing a compression check ASAP mate, then i would be looking at your boost and fuel curves from the rollers to see where the problem lies...

Can you post some up and we can have a look see? Surprised Scoff is baffled, must be something very weird to baffle the c1j god~!

GT 2560 R should be mental once spooled...?

There are many people that know more about c1j than me

how much boost are you running for that power?

Well if the head is in good working order and it's had some head work done to improve flow, the cam is a 285 and the turbo is big enough then there can't be many more things wrong.

A comp test is defo a good place to start.

Maybe the cam as mentioned might be worn.

Could the breather system be an issue???

I cant think what else it could be, your down pipe is a 2.5" job ain't it?

Lol don't panic fella, there has to be a reason why it ain't right, it's just a matter of time till its found.

If the basics are there it has to be something stupidly simple.

We just need to go through it one step at a time.

What are your charge temps like out of interest?

Approx 50 Deg C

I know what you're saying, and I'm not panic stricken, I was really gutted on Saturday but I've got my logic head on now, so like you say, I'll get on it after national day. ATM I'm just getting it back together after a few initial pokes here and there. Next thing to check is back pressure in the exhaust, I'll be welding a boss into the downpipe sometime soon. I don't expect to find any problems there.

It can't be my intake manifold can it???

BTW Ross - if you're reading this - the compressor housing is bolted on, I was looking at the back plate to core cir-clip.

Nah I used the same intake design remember.

Hang on a sec, you measured the lift on the cam right, was that lift on the inlet valves or did you measure the lift on the exhaust valves aswell?

are you running also efi system on your setup?

im having quite the same setup, and yesterday have left the car for engine maping. will be running 22psi with piper 285cams. hoping to break 200hp border! then we will be able to compare our setups if it wont blow

some ting is wrong mate i had my car map last day on gt28r and piper 285 at 1 bar and rev it only to 5krpm i done 176 whp and 180 torque efi setup to

i dont know where u get the time and patience from...im sure u will get to where u want to be eventually....good luck..

Cheers Jaffa - I've got to admit, I was pretty close to throwing it all in at 1am Sunday morning, but as a few have said, it's only metal etc, there is a problem somewhere...... I've just got to find the smegger (TM - Red Dwarf 1992-1996).

I think the phrase WIP is called for.

Have you checked what your turbo is pushing to make the 23psi into the engine? Could possibly be something in your intercooler or the intercooler has collapsed inside... Worth a check..

Also when you had the valve springs fitted were the seats relieved? Also your cam could be shot, ya may have to pull it out and have a look.. what you running the tappets at?

Hi Dave - my boost controller reference id taken directly from the compressor housing and my boost guage is taken from the inlet plenum, I'll have to look at differential between the 2 when I'm up and running again. I'm running a barrel charge cooler which when it was off last time looked good. A really good inspection wont hurt though.

The head work was done by CTM and when the springs are fully compressed, there is still a fair amount of travel left on the springs if need be, so I guess they are done. As for cam wear, I got half way through measuring last night when my oven spectacularly spat it's dummy out (element burnt out) It was like having a welder in my kitchen! and also had to clear a blocked drain, So I only managed to get the 1st 4 valves done which all came in at :-

1=9.56mm

2=9.35mm

3=9.7mm

4=9.5mm

I'll get the others done tonight all being well between the weekly shop and going out with the father in law.

My worry is that it's something I can't measure like the amount of air my head or inlet assembly will flow etc as I'm limited in knowing how many ft of air my engine flows etc, I'm not an engineer and I really struggle when it comes to stuff like that.

chargecooler shouldnt be the case if you are getting the right boost pressure in the intake manifold

OK Andy I think it will be a good idea to look what your turbo is doing, could well being pushing 50psi just to make the 23psi your seeing in the engine, which would take the turbo way out of its map.

What sort of inlet you running (did try to see some pics in your album, but couldn't) I can't see it being that mind..

Damn when it rain's it pours aye buddy!

Only other thing I could possibly think of is the inlet gasket is letting by when on boost, however, finding out if it's doing that is near impossible, I guess barring taking it of and looking for blow by marks?? Still I wouldn't do this just yet..

Hope this helps in some way fella.

these exducer/inducer size measurements seen with the housings in place , if they are i would say your turbo is more than up to the job, if there not and are o/a diameter sizes of compressor/turbine wheels then you are wasting your time with that set up

40mm turbine wheel is not enough

Thanks Dave - I'll be looking at the pressure from the compressor when it's back on the road, The inlet is a Micheal Tirianny affair - his 1st incarnation I'll load a picture up later. Head gasket is last resort, but if it needs it - off it will come.

Thanks a million for your input.

This is good experience for me btw everyone - I love knowing more about Fluffy, and this is a good learning spree for me.

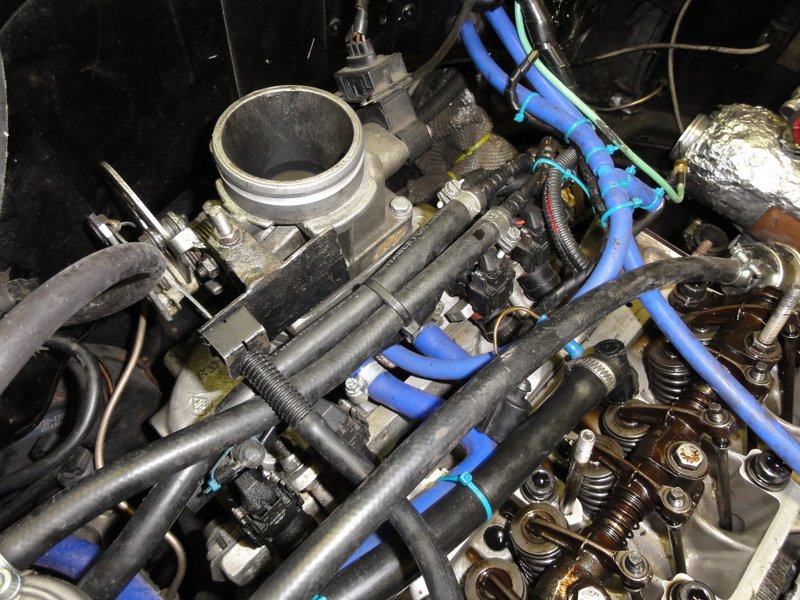

These are pics of the inlet manifold.

Rite - looking at the restriction side of things, I've got the 'duke' (engineer across the road from me) adapting a blanking boss to take a pipe off from the exhaust b4 any silencers etc so that I can measure if there is any pressure in the exhaust system. I'll keep us all posted.

This will go in the lambda boss all being well.

Andy that's the same inlet as I run, now I've not had my car in the dyno but it was good enough for an 11.7 quarter without gas and an 11.2 with.. So that defo shouldn't be your problem

Only thing I did do to mine was mastic/gasket seal all the throttle body to inlet parts, I didn't want to trust all those thin gaskets, probably over kill tbh, but didn't want any leaks on boost..

That's good to know, that's another thing to rule out, I made gaskets for the TB to adaptor to manifold from paper gasket, I'll strip that down and use some liquid gasket instead. I wonder if there is a way to test the complete circuit for leaks upto the head?? I'll have a think about that.

Last edited by TNT ANDY; 12-07-2012 at 06:19. Reason: Title change

Or just use some sump sealer

Unfortunately notyou can only really test up to the throttle body as its got to be blocked of to get the pressure up..

Will be good to finally see what it is, very strange fault.. Good luck buddy.

Bugger dude if you didn't have bad luck you'd have no luck at all.

Hope you get to the bottom of it soon. For some reason I've a gut feeling your issue is valve related don't know why just got that feeling.

And hope you and fluffy make it to national day for some beers.