Well, I thought it's about time I did a project thread on here.

I have owned my Raider for 8 years nearly now, in that time it's gone from everyday whip in which time it did over 45000 hard lead foot miles, it's had a few scrapes with telegraph poles and bmw's and such like and now barely does 1000 miles a year and spends most of its time sat in a garage in bits

So way back in 2010 the car had barely covered 500 miles in three years, was sat unloved on a car park under a cover almost completely forgotten aboutI had just bought a house with the Mrs and found in the December that my Mrs was pregnant with twins

I decided that I needed to pull my finger out and get it sorted before the little un's arrived otherwise it would have probably rotted to death

I got the old girl started and took her on some private roads for a bit of a warm up/shakedown. The lump had been mostly untouched since I purchased the car in 2005. The last time I had used the car was at the rtoc pod day in 2010 where it did a mid 13 with around 20psi on a t28. Anyway to cut a long story short the actuator vac pipe somehow came off and well you can guess what happened, lots of white smoke and a rather embarrassed me as I was just taking someone for a spin in it

It was at this point that project 12 seconds was born

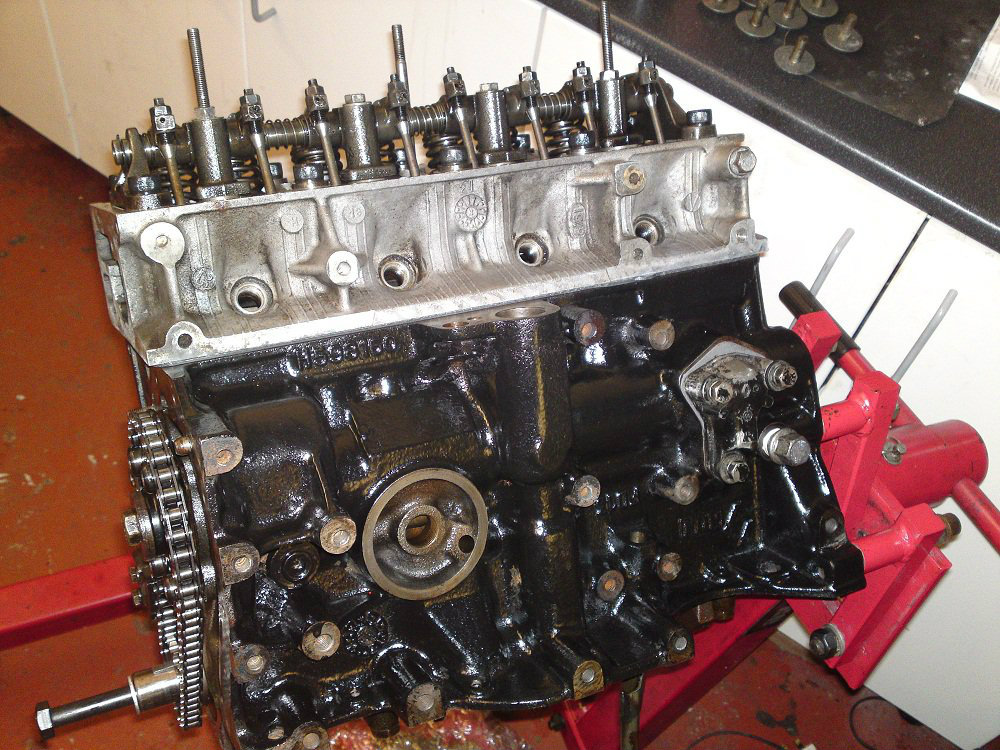

It was originally meant to be just a basic engine re-fresh and some more boost then one thing lead to another and it ended up being a complete re-build with lots of new shiny parts

The basic goal was to turn it into primarily a road car capable of doing a 12 second quarter mile. Some may see this as an easy target or been there done that but I was on a very limited budget and also a quite limited timescale with the impending arrival of the twinsAlso i must point out that my mechanical experience before this point was what i would class a not very much!!

I have met a few good freinds through RTOC who have helped in a big way when it came to picking things up so to speak. As an example when I first purchased the car in 2005 I thought the carb top was the turbo

(not sure I should really admit that)

So thanks to my very kind neighbour and good friend Dany I had some workspace that was under cover and the use of various tools such as a compressor and basically a very well kitted out spacious garage

This was the day I rolled it into the garage

Then after a few hours work

Basically I had blown the head gasket between cylinders 1 and 2, a contributing factor to this was the fact my engine actuallly had odd pistons, it had three dished pistons and one flat topped one, god knows how it ended up like that, it was before I purchased it anyway, even so, the motor did over 45000 miles like this and actually was in quite good health minus the damage

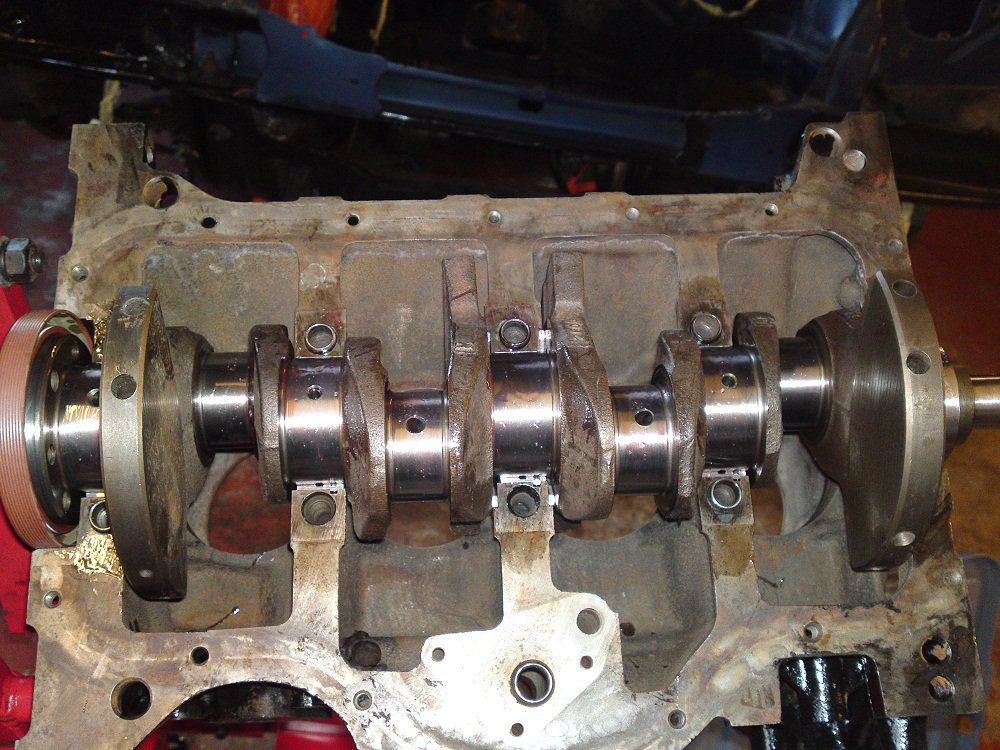

So I got the bottom end onto an engine stand and began to strip it down to a bare block.

At this point I was still intent on re-using the majority of the old parts and just re-assembling with all new bearings gaskets/seals. The issue I had was that I needed to find a single dished low comp piston to replace the flat topped one from my engine. I did manage to find a set of low comp pistons and rod, one of them had spun a bearing and was scrap but the rest appered to be usable. I set about purchasing all the required parts to put the bottom end back together.

To cut a long story short when I started to put the block back together the new replacement low comp pistons I had purchased kept on pinching the crank when tourqed upno matter what I did they were not for moving freely at all. so i wrapped the block in a bin liner and pretty much left it at that for a few week while i saved up some cash and decided on my next move.

Thats all for now as stupid slow photobucket is really starting to get on my nerves

Plenty more progress and pictures to come, to take it up the present day

Reply With Quote

Reply With Quote

Can't wait for part 2...

Can't wait for part 2...

)

)

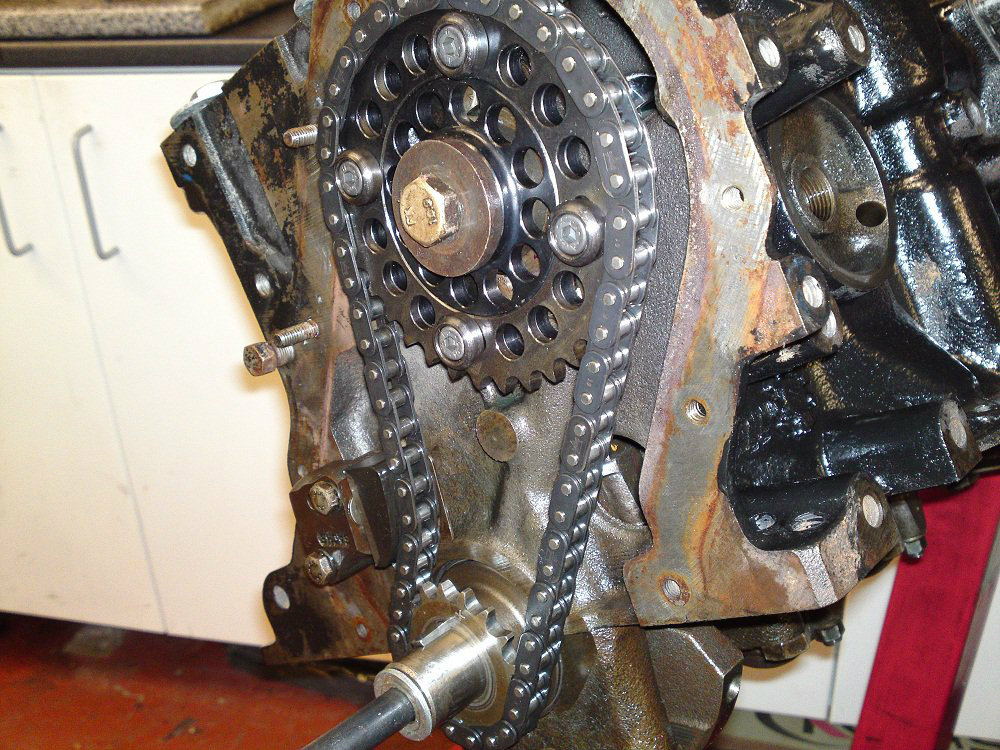

) for me, so I took him up on his offer and for good measure got him to clean up the block, I'm pressuming they hot washed it as it came back immaculate.

) for me, so I took him up on his offer and for good measure got him to clean up the block, I'm pressuming they hot washed it as it came back immaculate.

) If you look closely you can see the scars from the small brush I had with a telegraph pole(tungy drivers side arch

) If you look closely you can see the scars from the small brush I had with a telegraph pole(tungy drivers side arch ) and also the scar from the little incident with a BMW. (passenger side bonnet hinge

) and also the scar from the little incident with a BMW. (passenger side bonnet hinge

.

.

.

.

so I had to bridge the connections with a small bit of wire when I needed the fan to come in, the day was pretty much the same as the one before and was baking hot, to say it got fairly tostey in the car was an understatement, as I had the heater on full pelt also

so I had to bridge the connections with a small bit of wire when I needed the fan to come in, the day was pretty much the same as the one before and was baking hot, to say it got fairly tostey in the car was an understatement, as I had the heater on full pelt also