Originally Posted by

Haz

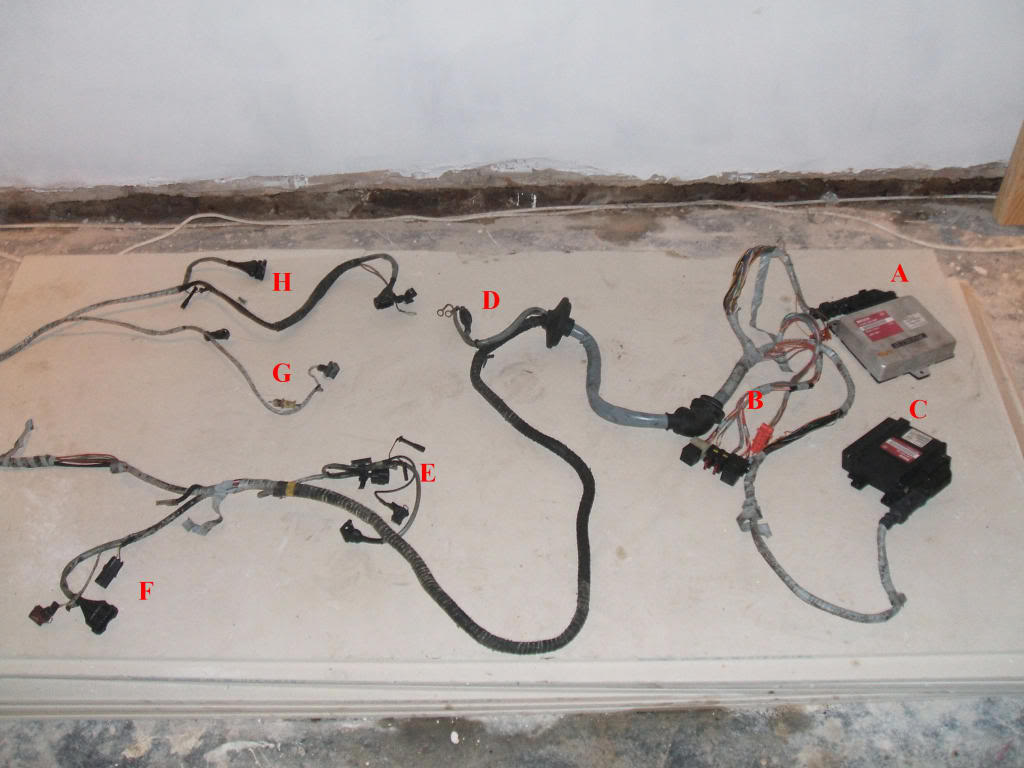

unlabelled connectors

a2,3,4 test points

e1,2 test points

e3 volvo sensor in sump for volvo gauges

e4 knock sensor

f4 ecu temp sensor on front of block

g1 air temp sensor in turbo inlet pipe for volvo gauges

g2 lambda probe

g3 test point

h1 volvo boost solinoid

h5,6 test points

your better off keeping all the original sensors of the cars original engine and fit with unions etc so that all the gauges calibrate correctly, even sensors from other cars of the same model can read slightly out.

Reply With Quote

Reply With Quote

. Pics updated

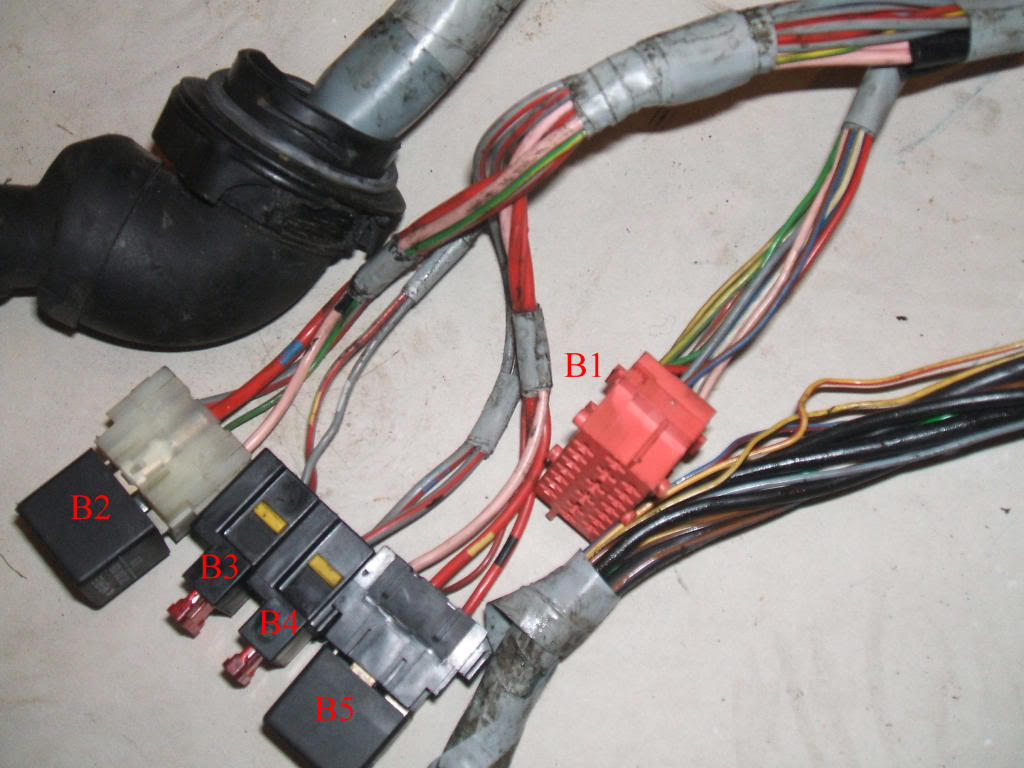

. Pics updated what is the best way to wire it all up? I was going to use the renault connector and wire the volvo loom to that. But what i dont get is what wires go where and if theres any wires on the renault loom that i need to keep like the reverse lights and alternator and starter motor leads? also there seems to be no power lead for the volvo loom like on the renault so should that be kept? any help would be great or if anyone could tell me what wires do what on the renault connector? cheers guys..

what is the best way to wire it all up? I was going to use the renault connector and wire the volvo loom to that. But what i dont get is what wires go where and if theres any wires on the renault loom that i need to keep like the reverse lights and alternator and starter motor leads? also there seems to be no power lead for the volvo loom like on the renault so should that be kept? any help would be great or if anyone could tell me what wires do what on the renault connector? cheers guys..